Chrome Moly Vanadium Steel: Unveiling Its Strength and Versatility

In the world of materials science, certain alloys stand out for their exceptional properties and diverse applications. Among these, chrome moly vanadium steel holds a prominent position. This high-strength, low-alloy steel is renowned for its superior toughness, weldability, and resistance to corrosion, making it a preferred choice in demanding industries. Let’s delve into the composition, properties, applications, and advantages of chrome moly vanadium steel.

Understanding Chrome Moly Vanadium Steel

Chrome moly vanadium steel, often abbreviated as chrome-moly-vanadium or CrMoV, is a family of alloy steels containing chromium, molybdenum, and vanadium as the primary alloying elements. The specific percentages of these elements can vary depending on the desired properties and application. These alloying elements contribute significantly to the steel’s enhanced mechanical properties and performance.

Composition and Alloying Elements

The typical composition of chrome moly vanadium steel includes:

- Chromium (Cr): Improves corrosion resistance, hardenability, and high-temperature strength.

- Molybdenum (Mo): Enhances strength, toughness, and resistance to creep at elevated temperatures.

- Vanadium (V): Refines grain structure, increases strength, and improves wear resistance.

- Carbon (C): Contributes to hardness and strength, but the percentage is carefully controlled to maintain weldability.

- Manganese (Mn): Improves hardenability and strength.

- Silicon (Si): Acts as a deoxidizer during the steelmaking process and enhances strength.

The precise balance of these elements is crucial for achieving the desired combination of properties in chrome moly vanadium steel. Different grades of chrome moly vanadium steel exist, each tailored to specific applications.

Key Properties of Chrome Moly Vanadium Steel

Chrome moly vanadium steel boasts a range of impressive properties that make it suitable for various demanding applications:

- High Strength: Exhibits excellent tensile and yield strength, allowing it to withstand significant loads and stresses.

- Toughness: Possesses good impact resistance, preventing brittle fracture under dynamic loading conditions.

- Weldability: Can be readily welded using various techniques, facilitating fabrication and repair.

- Corrosion Resistance: Offers improved resistance to corrosion compared to plain carbon steel, particularly in mild environments.

- High-Temperature Strength: Retains its strength and creep resistance at elevated temperatures, making it suitable for high-temperature applications.

- Hardenability: Can be hardened through heat treatment to achieve desired hardness and wear resistance.

These properties make chrome moly vanadium steel a versatile material for a wide range of engineering applications.

Applications of Chrome Moly Vanadium Steel

The exceptional properties of chrome moly vanadium steel make it an ideal choice for numerous applications across various industries:

Aerospace Industry

In aerospace, chrome moly vanadium steel is used in critical components such as aircraft landing gear, engine mounts, and structural parts. Its high strength-to-weight ratio and fatigue resistance are crucial for ensuring aircraft safety and performance. [See also: Aerospace Material Innovations]

Automotive Industry

Chrome moly vanadium steel finds applications in automotive components that require high strength and durability. These include connecting rods, crankshafts, suspension components, and roll cages. Its ability to withstand high stresses and impacts makes it a reliable material for performance vehicles and racing applications.

Oil and Gas Industry

The oil and gas industry utilizes chrome moly vanadium steel in pipelines, pressure vessels, and drilling equipment. Its resistance to corrosion and high-temperature strength are essential for handling harsh operating conditions and corrosive fluids. This steel ensures the integrity and safety of critical infrastructure in the oil and gas sector. [See also: Advanced Pipeline Materials]

Power Generation

In power plants, chrome moly vanadium steel is employed in boiler tubes, turbine blades, and steam pipes. Its high-temperature strength and creep resistance are crucial for withstanding the extreme conditions within power generation systems. The material’s durability ensures the efficient and reliable operation of power plants.

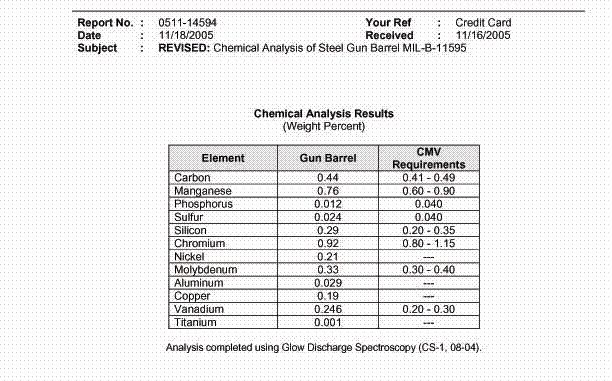

Defense Industry

The defense industry relies on chrome moly vanadium steel for manufacturing armored vehicles, gun barrels, and other critical components. Its high strength and toughness provide essential protection and ensure the reliability of military equipment in demanding environments. The steel’s ability to withstand extreme conditions is paramount for defense applications.

Other Engineering Applications

Beyond these major industries, chrome moly vanadium steel is also used in various other engineering applications, including:

- High-pressure hydraulic systems

- Forged components

- Gears and shafts

- Fasteners and bolts

Advantages of Using Chrome Moly Vanadium Steel

Choosing chrome moly vanadium steel offers several significant advantages:

- Enhanced Strength and Toughness: Provides superior mechanical properties compared to plain carbon steel.

- Improved Weldability: Facilitates easy fabrication and repair.

- Corrosion Resistance: Offers better resistance to corrosion in various environments.

- High-Temperature Performance: Maintains strength and creep resistance at elevated temperatures.

- Versatility: Suitable for a wide range of applications across diverse industries.

- Extended Service Life: Its durability and resistance to wear contribute to a longer service life for components and equipment.

These advantages make chrome moly vanadium steel a cost-effective and reliable material choice for critical applications.

Heat Treatment of Chrome Moly Vanadium Steel

Heat treatment plays a crucial role in optimizing the properties of chrome moly vanadium steel. Common heat treatment processes include:

- Annealing: Softens the steel and improves machinability.

- Normalizing: Refines the grain structure and improves toughness.

- Quenching: Hardens the steel by rapid cooling.

- Tempering: Reduces brittleness and increases toughness after quenching.

The specific heat treatment parameters depend on the desired properties and the grade of chrome moly vanadium steel. Proper heat treatment is essential for achieving the optimal performance characteristics of the steel.

Welding Chrome Moly Vanadium Steel

Welding chrome moly vanadium steel requires careful consideration to maintain its mechanical properties and prevent cracking. Preheating and post-weld heat treatment (PWHT) are often necessary to ensure a sound weld. Common welding processes include:

- Gas Tungsten Arc Welding (GTAW)

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW)

Selecting the appropriate filler metal and welding parameters is crucial for achieving a strong and ductile weld joint. Proper welding techniques and heat treatment procedures are essential for maintaining the integrity of the steel.

Future Trends in Chrome Moly Vanadium Steel

The development of chrome moly vanadium steel continues to evolve with ongoing research and advancements in materials science. Future trends include:

- Development of new alloy compositions: Tailoring the alloying elements to achieve specific properties for emerging applications.

- Improved processing techniques: Optimizing manufacturing processes to enhance the steel’s performance and reduce costs.

- Advanced heat treatment methods: Developing more precise and efficient heat treatment processes to achieve desired microstructures and properties.

- Applications in additive manufacturing: Exploring the use of chrome moly vanadium steel in 3D printing for creating complex components.

These advancements will further expand the applications of chrome moly vanadium steel and enhance its performance in various industries.

Conclusion

Chrome moly vanadium steel is a versatile and high-performance alloy steel that offers a unique combination of strength, toughness, weldability, and corrosion resistance. Its applications span across numerous industries, including aerospace, automotive, oil and gas, power generation, and defense. By understanding its composition, properties, and advantages, engineers and designers can effectively utilize chrome moly vanadium steel to create durable, reliable, and high-performing components and structures. As materials science continues to advance, chrome moly vanadium steel will remain a critical material for demanding engineering applications. [See also: The Future of Steel Alloys]