Precision Perfected: Mastering Gunsmithing with Torque Wrenches

In the meticulous world of gunsmithing, precision isn’t just a virtue; it’s a necessity. Every component, every screw, every adjustment plays a critical role in the firearm’s performance, safety, and longevity. Among the arsenal of specialized tools that a gunsmith relies on, the torque wrench stands out as a cornerstone of accuracy and reliability. This article delves into the significance of gunsmithing torque wrenches, exploring their types, applications, and why they are indispensable for achieving optimal results.

The Importance of Torque Control in Gunsmithing

Over-tightening or under-tightening screws and fasteners can lead to a cascade of problems. Over-tightening can damage threads, strip screws, or even crack receiver components. Under-tightening, on the other hand, can result in parts loosening during use, leading to malfunctions or even dangerous situations. A gunsmithing torque wrench ensures that each fastener is tightened to the precise specification recommended by the manufacturer, minimizing the risk of damage and maximizing performance.

Consider the installation of a scope mount. Too much torque can crush the scope tube, rendering it useless. Too little torque, and the scope may shift during firing, throwing off your zero. A gunsmithing torque wrench eliminates the guesswork, providing repeatable and accurate results every time. This control is paramount for maintaining the integrity and functionality of the firearm.

Types of Gunsmithing Torque Wrenches

Several types of torque wrenches are suitable for gunsmithing, each with its own advantages and disadvantages:

- Beam Torque Wrenches: These are the simplest and most affordable type. They feature a beam that deflects when torque is applied, with a scale indicating the amount of torque. While relatively inexpensive, they can be less accurate than other types and require careful visual reading.

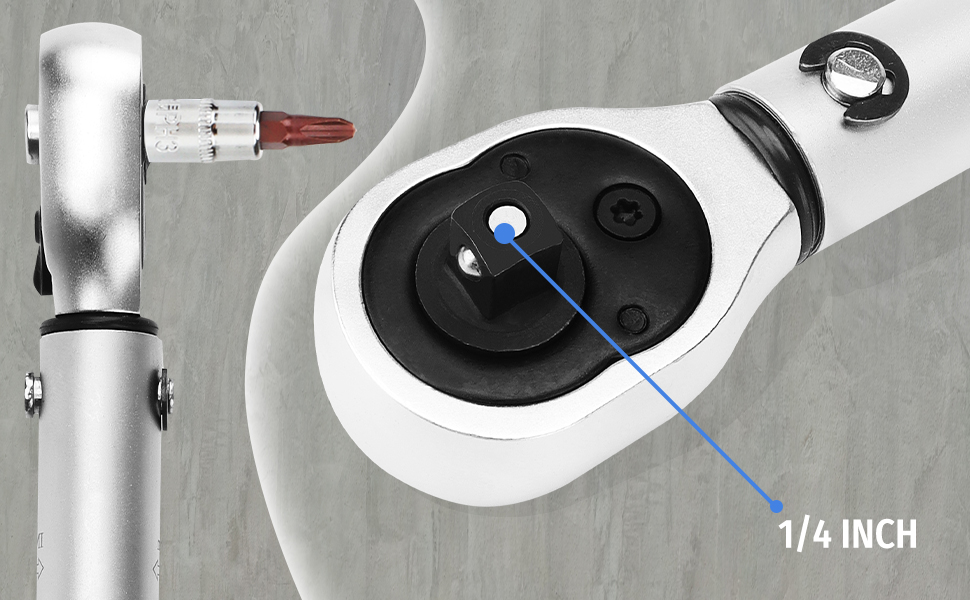

- Click-Type Torque Wrenches: These are the most common type used in gunsmithing. They allow you to set a desired torque value, and the wrench emits an audible “click” when that value is reached. They are more accurate than beam wrenches and easier to use, but they require periodic calibration.

- Digital Torque Wrenches: These are the most accurate and advanced type of torque wrench. They feature a digital display that shows the applied torque in real-time. They often include features such as data logging and multiple units of measurement. Digital torque wrenches are generally more expensive than other types, but their accuracy and features make them a worthwhile investment for serious gunsmiths.

- Torque Screwdrivers: These are smaller, specialized torque wrenches designed for low-torque applications, such as scope ring screws or action screws. They are typically click-type or digital and offer precise control over small fasteners.

Selecting the Right Torque Wrench for Gunsmithing

Choosing the right gunsmithing torque wrench depends on several factors, including the types of firearms you work on, the range of torque values you need, and your budget.

- Torque Range: Consider the range of torque values you will typically encounter in your gunsmithing work. Most firearm components require torque values between 15 and 65 inch-pounds, but some applications may require higher or lower values. Choose a torque wrench that covers the range you need.

- Accuracy: Accuracy is paramount when it comes to torque wrenches. Look for a wrench that is certified to meet industry standards, such as ASME or ISO. Digital torque wrenches generally offer the highest accuracy, followed by click-type wrenches. Beam wrenches are the least accurate.

- Ease of Use: Choose a torque wrench that is easy to use and read. Click-type wrenches are generally the easiest to use, as they provide an audible and tactile indication when the desired torque value is reached. Digital torque wrenches offer the advantage of a clear digital display.

- Durability: Gunsmithing tools can take a beating, so choose a torque wrench that is built to last. Look for a wrench made from high-quality materials, such as steel or aluminum.

- Budget: Torque wrenches range in price from a few dollars for a basic beam wrench to several hundred dollars for a high-end digital wrench. Determine your budget and choose a wrench that offers the best value for your money.

Essential Applications of Torque Wrenches in Gunsmithing

Gunsmithing torque wrenches are essential for a wide range of tasks, including:

- Scope Mounting: Ensuring proper torque on scope rings and bases is crucial for maintaining zero and preventing damage to the scope.

- Action Screws: Properly torquing action screws is essential for accuracy and consistent performance.

- Trigger Installation: Many aftermarket triggers require specific torque values for optimal function and safety.

- Barrel Installation: When installing or re-barreling a firearm, proper torque is critical for headspacing and accuracy.

- Stock Installation: Ensuring the correct torque on stock screws prevents stock movement and maintains consistent bedding.

Best Practices for Using a Gunsmithing Torque Wrench

To ensure accurate and reliable results, follow these best practices when using a gunsmithing torque wrench:

- Calibrate Regularly: Click-type and digital torque wrenches should be calibrated regularly to maintain accuracy. Follow the manufacturer’s recommendations for calibration frequency.

- Use the Correct Socket: Use the correct size and type of socket for the fastener you are tightening. A loose or ill-fitting socket can lead to inaccurate torque readings.

- Apply Torque Slowly and Smoothly: Avoid jerking or applying excessive force. Apply torque slowly and smoothly until the desired value is reached.

- Hold the Wrench Properly: Hold the torque wrench at the handle, not the head. Gripping the head can affect the accuracy of the reading.

- Store Properly: Store your torque wrench in a clean, dry place. Avoid dropping or subjecting it to extreme temperatures.

Specific Examples of Torque Values in Gunsmithing

Here are some common examples of torque values used in gunsmithing. Always refer to the manufacturer’s specifications for your specific firearm and components:

- Scope Rings: 15-25 inch-pounds

- Scope Bases: 20-30 inch-pounds

- Action Screws (Rimfire): 15-20 inch-pounds

- Action Screws (Centerfire): 45-65 inch-pounds

- Trigger Adjustment Screws: 5-10 inch-pounds

The Future of Torque Control in Gunsmithing

As firearms technology advances, the demand for precision and accuracy in gunsmithing will only increase. Digital torque wrenches with advanced features such as data logging and wireless connectivity are becoming more common, allowing gunsmiths to track and analyze torque data for improved quality control. Furthermore, the integration of torque wrenches with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems is streamlining the gunsmithing process and enabling more precise and repeatable results.

Conclusion: The Indispensable Gunsmithing Torque Wrench

In conclusion, the gunsmithing torque wrench is an indispensable tool for any gunsmith who values precision, safety, and reliability. By providing accurate and repeatable torque control, it minimizes the risk of damage, maximizes performance, and ensures the longevity of firearms. Whether you are a professional gunsmith or a serious hobbyist, investing in a quality torque wrench is an investment in the quality and safety of your work. Understanding the different types of gunsmithing torque wrenches, selecting the right one for your needs, and following best practices for use are crucial for achieving optimal results. Embrace the power of precise torque control and elevate your gunsmithing skills to the next level. The use of a gunsmithing torque wrench ensures that every screw, every component, is perfectly in place, contributing to a safer and more reliable firearm. This gunsmithing torque wrench precision is what separates a good gunsmith from a great one. Don’t underestimate the importance of a good gunsmithing torque wrench in your toolkit. A quality gunsmithing torque wrench is an investment that pays dividends in accuracy and peace of mind. Remember to always consult the firearm manufacturer’s specifications when using your gunsmithing torque wrench. And lastly, using a gunsmithing torque wrench is a testament to a gunsmith’s commitment to quality and precision. [See also: Choosing the Right Gunsmithing Tools] [See also: Firearm Maintenance Best Practices] [See also: Advanced Gunsmithing Techniques]